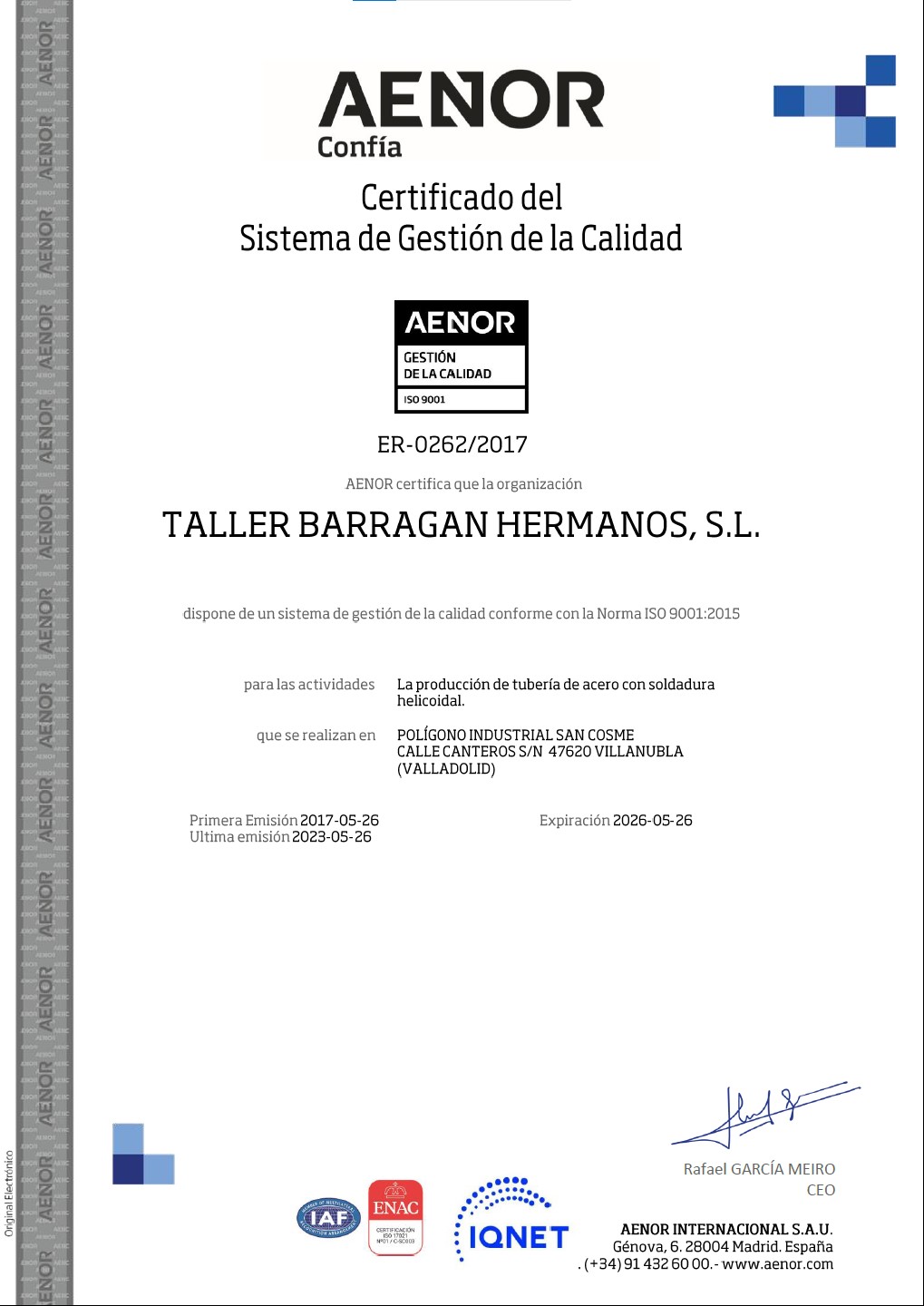

Quality Control

Our Quality Policy

Our highly-skilled manpower is dedicated to producing the finest quality steel pipe, meeting a wide variety of material specifications. Their knowledge and experience of metal properties, welding procedures and quality control have set the pace and standard expected by our customers.

Welding of hot rolled steel coils takes spiral form after passing through preforming and forming rolls. Excellent exterior weld quality at high production speeds is provided by double submerged arc welding process. Manufactured pipes are cut to the desired lengths at the exit of the pipe machine. Pipe ends are beveled by means of carbide machining for accurate on-site welding.

The materials are inspected at arrival, their quality certificates revised and included in data base for the traceability system. After manufacturing is completed, the pipe will be subject to final inspection for the compliance to customer requirements.

The automated double submerged arc-welding process is qualified in accordance with the European Standard EN 15614-1 Edition 2005.

The traceability of the materials with which each batch of pipes is manufactured is ensured thanks to:

– A TBH proprietary computer system, which, among other things, registers the steel quality certificates and the welding materials used in a database.

– The marking of each tube produced with a reference code.

983 56 00 31

983 56 00 31